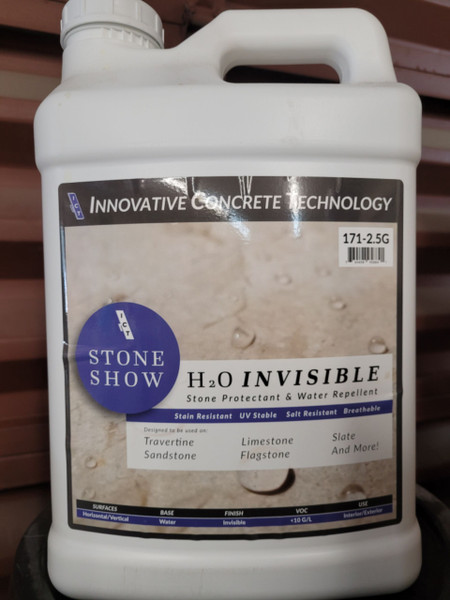

Product Overview

ICT Stone Show H2O Invisible is a clear drying water-repellent that does not change the color characteristics of the substrate being treated. Stone Show H2O Invisible has been specially formulated to be the ideal option for natural stones that must allow moisture to escape without allowing moisture the reenter through the non-film-forming barrier created by the proper installation of Stone Show H2O Invisible. By disallowing the penetration of moisture, Stone Show H2O Invisible will also help against other complications cause by the presence of water such as efflorescence, staining, spalling, and some cracking. Stone Show H2O Invisible does not create a film over the surface and will not make the surface any more slippery than before application of Stone Show H2O Invisible once excess has been removed. Stone Show H2O Invisible will keep surfaces beautiful and protected. Longevity, which is typically around 12-24 months, and can last longer on porous surfaces, and will be determined by the amount of Stone Show H2O Invisible that is absorbed into the substrate.

If color enhancement is desired, use Stone Show H2O Enhancer (170) instead.

FEATURES & BENEFITS

| COLOR ENHANCEMENT | ONE-WAY WATER REPELLENT |

| STAIN RESISTANCE | EASY MAINTENANCE |

| LOW V.O.C. | INHIBITS BIO GROWTH |

| EFFLORESCENCE RESISTANCE | PENETRATING |

| BREATHABLE | NON FILM FORMING |

COVERAGE

Coverage rates will vary depending on substrate, textures, porosity, and application methods.

Porous, Textured Surfaces — 75-125 sq. ft. per gallon

Semi-Porous Surfaces — 100-200 sq. ft. per gallon

Dense, Smooth Surfaces — 200-400 sq. ft. per gallon

Designed to be used on

| TRAVERTINE | LIMESTONE | SLATE |

| SANDSTONE | FLAGSTONE | AND MORE! |

DO NOT apply ICT Stone Show H2O Enhancer when air or surface temperature is below 45°F or is expected to fall to the point before application is dry. Low temperatures and high humidity will effect drying and curing times.

DO NOT apply ICT Stone Show H2O Enhancer to new cement, mortar or grout. Allow these products to harden for a minimum of 0-4 days before application.